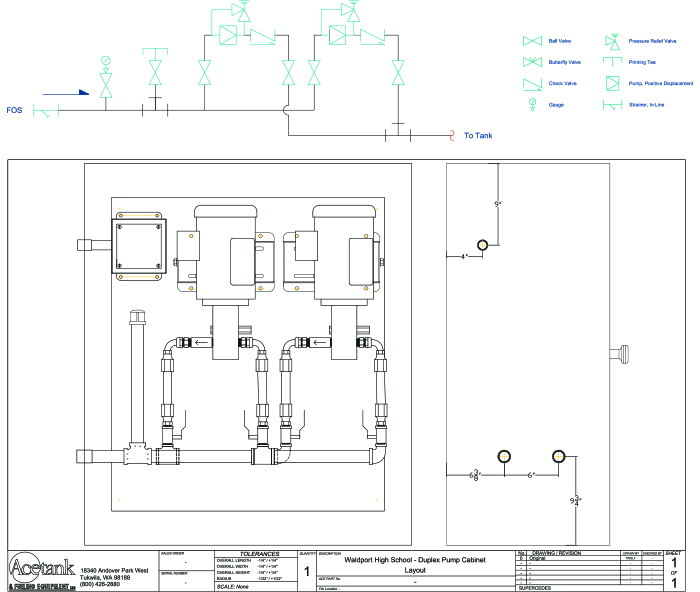

Ace FuelSafe Pump Sets use Rotary Gear, positive displacement, continuous duty pump with internal relief mounted in an outdoor rated enclosure with lockable door, spill containment and leak switch. Pump set is designed to work with Ace FuelSafe UL-508 control panel.

Dual Pump set controls standard is lead/lag. Each pump is sized for full duty/fill demand. Properly sized flow switch is included with each pump set but is shipped loose for installation at Day tank. If ordering ILOP the flow switch will be located at ILOP inlet. Remote mount allows for detection of line shear preventing an unintentional fuel spill.

Rugged Ductile Iron Construction Positive Displacement

Includes:

• Fuel oil supply lines should be sized to not exceed more than 20 inches of mercury as measured at the pump inlet manifold.

• It is very important to carefully size the fuel oil supply and return lines to minimize the friction losses and not exceed this restriction.

• It is recommended to install a foot valve in the supply line for priming purposes. It is also recommended to install a fusible link valve and anti-siphon valve in the fuel supply line at the high point in the system.

• To minimize friction losses a solenoid actuated anti-siphon valve may be used in lieu of a mechanical valve.

Includes:

• Y type suction strainer with bottom clean out and plug.

• Priming Tee with riser pipe, isolation valve and dust plug.

• (Optional) Vacuum gauge with isolation valve.

• (Optional) Fusible globe valve. (Shipped Loose)

• (Optional) Stainless steel flex connectors w/; swivel adapters. (Shipped Loose)

Our proprietary Infinite Loop Overfill Prevention System eliminates the need for complex reverse overflow pumping systems. Our system uses supply pump pressure to safely return fuel back to the main tank without relying on another level switch to start a reverse overflow pump.

Ace FuelSafe Cabinet Dispensing Package Specification:

• Powder Coat Finish System inside and out.

• Sturdy Piano Hinge Doors with Gasketed Enclosure.

• Lockable Door Hardware with Oversized Handles for cold weather operation.

• Reinforcement as needed to support equipment.

• As built/ spec sheet holder.

• Watertight piping and conduit penetrations.

• Continuous Duty Pumps with Internal Relief.

• Y type suction strainer with bottom clean out and plug.

• Priming Tee with riser pipe, isolation valve and dust plug.

• Optional Vacuum gauge with isolation valve.

• Ace QC certification.

Fuel Maintenance

Fuel Maintenance (water and particulate removal) packages can be offered in a stand-alone configuration or as part of the FuelSafe Day Tank package. This option includes fuel filtration skid as integral part of day tank system eliminating the need for added infrastructure required to support a stand-alone fuel maintenance system, eliminating system complexity and minimizing cost impacts to the project.

The integral fuel maintenance system allows for the use of existing fuel supply and return lines as the fuel supply pumps act as both the prime mover for the fill operation and the fuel maintenance cycles. This ensures clean fuel, regular exercise schedules for supply pumps and minimizes installation complexities.